Ethylene Oxide Production, Pdf Is The Liquid Phase H2o2 Based Ethylene Oxide Process More Economical And Greener Than The Gas Phase O2 Based Silver Catalyzed Process

Now nearly all the worlds EO capacity is based on direct oxidation with oxygen generally preferred. Ethylene oxide is produced by the direct oxidation of ethylene over suitable catalysts at a temperature of around 200C to 300C and a pressure of 10 bar.

Figure 5 From No A 10 117 Ethylene Oxide Semantic Scholar

Production of ethylene oxide began in 1914 by the chlorohydrin process the main method used until 1937 in which ethylene chlorohydrin is converted to ethylene oxide by reaction with calcium oxide.

Ethylene oxide production. It is a major commodity chemical that is manufactured throughout the world. Industrial production started in 1925 using the chlorohydrin pro-cess. Annual worldwideproductioncapacityisca15 106 t.

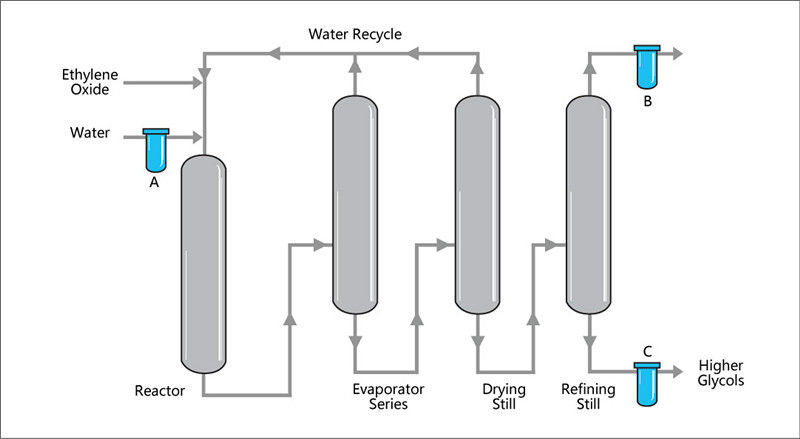

Ethylene Oxide Production Ethylene oxide EO is used primarily as a chemical intermediate in making ethylene glycol and certain plastics. Ethylene oxide production Oxidation of ethylene by peroxy acids. Ethylene oxide is prepared by epoxidation of alkenes like ethylene with peroxy.

Ethylene oxide is used as a chemical intermediate primarily for the production of ethylene glycols but also for the. The reaction network consists of the desired mildly. Monoethylene glycol MEG accounts for more than 90 of the market for EG.

It is manufactured by passing ethylene and air under pressure over a chemical catalyst like. Production of Ethylene Oxide Ethylene oxide C2H4O is a color-less flammable gas or liquid. It is considered to be one of the most versatile chemical intermediates owing to its high reactivity.

Production and importance of ethylene oxide have steadily grown. Ethylene oxide has an estimated half-life in air ranging from 69 to 149 days while its half-life in water ranges from 12 to 14 days in sterile deionized and natural river water. Ethylene oxide EO and ethylene glycol EG are widely used industrial organic intermediates.

Ethylene oxide can be produced by reacting oxygen O 2 and ethylene C 2 H 4 at temperatures of 200 300C and pressures of 10 20 bara. METEOR EO-RETRO 2000 a more efficient catalyst Dow developed the Most Effective Technology for Ethylene Oxide Reaction METEOR catalysts to increase the performance and. The present invention relates to a process for the production of ethylene oxide.

Since 1937 when Union Carbide opened its first EO plant partial oxidation of ethylene has been performed using the Ag-based catalyst system developed by Theodore Lefort. Ethylene Oxide EO Production and Manufacturing Process. The typical yield of this reaction is up to 80 90.

In 1995 their production volumes ranked them among the top twenty organic chemicals in the United States. The EO production process is energy intensive and creates direct CO 2 emissions making it critical to deploy transformative technologies that go beyond business as usual. Ethylene oxide is a versatile compound used in the production of other chemicals for a variety of industrial applications and everyday consumer products including household cleaners personal care items and fabrics and textiles.

In 1931 LEFORT 9 discovered the direct catalytic oxidation of ethylene 74-85-1 which gradually superseded the chlorohydrin process. Currently ethylene oxide is produced by direct oxidation of ethylene with air or oxygen. Ethylene oxide EO was initially manufactured using ethylene chlorohydrin as an intermediate but this route has been superseded by the direct oxidation of ethylene with air or oxygen.

The Current State of the Production of Ethylene Oxide Production Catalysts in Russia Based on the results of the works set out in 88 89 in 1995 Kazanorgsintez organized the production of an ETOKS-Yu catalyst for the air processes 90 based on amine silver complexes with the additions of Cs carbonate and Mg Ca and Zn borates supported onto a small-pore ring-shaped carrier. Because of its molecular structure ethylene oxide is one of the most versatile chemical intermediates. Ethylene oxide is produced by the catalytic oxidation of ethylene.

The worldwide production of ethylene oxide EO currently exceeds 20 MM tyr.

Technology Profile Ethylene Oxide Production From Ethylene Chemical Engineering Page 1

Ethylene Glycol Production Applications Feature Tec

The Route Towards Sustainable Production Of Ethylene Glycol From A Renewable Resource Biodiesel Waste A Review Catalysis Science Technology Rsc Publishing

Ethylene Oxide Production Applications Feature Tec

Optimal Reaction Concept And Plant Wide Optimization Of The Ethylene Oxide Process Sciencedirect

File Ethylene Oxide Production Plant Svg Wikimedia Commons

Manufacturing Process Antifreezethe Chemical

Improved Process Design And Optimization Of 200 Kt A Ethylene Glycol Production Using Coal Based Syngas Sciencedirect

Pdf Is The Liquid Phase H2o2 Based Ethylene Oxide Process More Economical And Greener Than The Gas Phase O2 Based Silver Catalyzed Process

Https Www Ugr Es Tep028 Pqi Descargas Industria 20quimica 20organica Tema 5 Oxido Etileno A10 117 Pdf

A Pfd For Ethylene Oxide Plant 4 Download Scientific Diagram

Ethylene Glycol Production Chemical Engineering

Ethylene Oxide By Rumaanah Ismail

Optimal Design Of Gas Expanded Liquid Ethylene Oxide Production With Zero Carbon Dioxide Byproduct Industrial Engineering Chemistry Research X Mol

Figure 3 1 From A Simulation Model Of A Reactor For Ethylene Oxide Production Semantic Scholar

Preparation Of Glycols From Ethylene Oxide Patent 0133763

Ethylene Oxide Production Ethylene Oxide

Production Of Ethylene Glycol Petrochemical Processes Riley Doiron